Continuous Distillation

An uninterrupted distillation process where a continuous flow of distillate is collected as output. The raw material may be continuously fed into the still at one point or reloaded without interrupting the collection of distillate.

When performing a batch distillation using the simple distillation process the still needs to be continuously emptied of the spent material and refilled for each individual distillation run, interrupting the collection of the distillate. This is not so for continuous distillation as there are no interruptions in the distillation process.

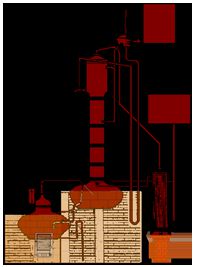

A prime example of continuous distillation is the professional Armagnac Type Alembic Still with which high grade alcohol can be obtained in a single run which would normally require double or triple distillations using the simple distillation technique. In the fractional column a continuous feed of an alcoholic solution such as wine is introduced in the column. As this solution comes into contact with the hot rising vapours, from the boiler, the more volatile components are stripped from the solution and rise up the column. These alcohol vapours are drawn off and condensed after continuous rectifications (discussed further in the fractional distillation method). The more dense components or the less volatile components of the alcoholic solution stream back down into the boiler.

Fractional and continuous distillations methods are only descriptive of the various processes that take place and all may be incorporated into a single still design.

The graceful Charentais Alembic Still developed in France in the early 16th century to distil fine cognacs from Charentais wines is a semi continuous distillation process as you may allow for a continuous feed of wine for distillation.

This unit is comprised of an alembic pot attached to an onion shaped dome or preheater and condensing unit. The wine to be distilled in this case is preheated in the onion shaped dome by the flow of vapour from the swan neck tubing of the alembic pot as it flows in the direction towards the condenser unit. The wine in the preheater in turn is transferred to the alembic pot via a connecting tube between the two for distillation, thus closing the circuit.

The Portuguese Arrastre de Vapour distilling system is yet another example of a semi continuous distillation design.

This system is very versatile and may be constructed according to the clients' specific needs. A two or more column system allows for continuous drawing off of distillate as while one column is emptied and refilled the distillation process continues in the second column.

Professional continuous distillation systems have obvious applications for large scale high grade alcohol production with unlimited potential for producing any number of alcoholic spirits. The hobbyist distiller may want to experiment with the Charentais Alembic Still, fully functional yet beautiful in design. The Portuguese Arrastre de Vapour is a multi-purpose distilling system, due to its versatility, and may be used for the distillation of spirits, essential oils, medicinal herbal extracts, perfumes, rosewater etc.