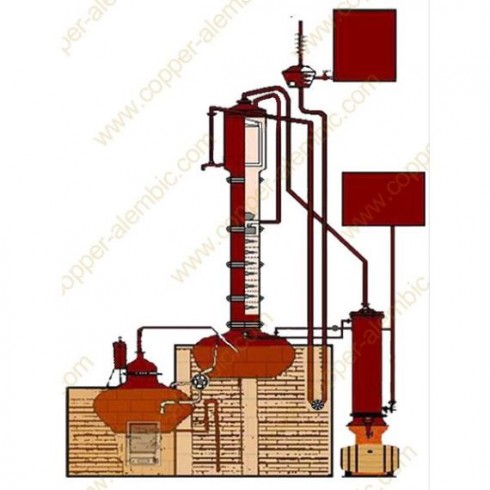

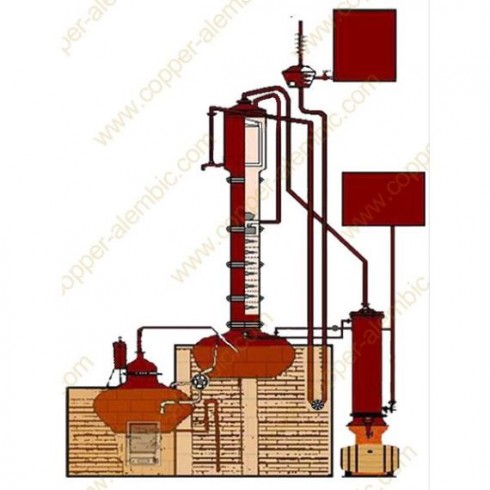

Quite a large area is required to assemble the unit - 8 metres in height and a brick structure to conserve heat. This still incorporates almost all of the general principles of the stills currently in use today. Its most important feature is that it was designed to operate continuously. That is to say that once in operation, the liquid to be distilled is fed continuously at one end and distillate is recovered continuously at the other end. This continuous distillation process results in time and energy savings.

Before initiating distillation the complete system must be filled with wine, which includes boilers, wine deposit and preheating chamber. An automatic float at the beginning of the system and a release valve control the flow of wine from the wine deposit to the preheating chamber at the top of the column. The column has a number of plates introduced in it to increase the purity of the rising vapours. These are literally large perforated metal plates or trays over which the wine stream flows and cascades down. The vapours rising from the boiler bubble up and mingle with the cooler wine stream thus preheating it. The lower temperature of the wine stream condenses the less volatile components in the vapour and fall back. This process continues up the column on each tray and consequently the more volatile higher proof vapours will collect at the top and are drawn off. Obviously the more plates there are in a column, the greater the purity of the distillate. This continuous condensation and vaporisation of the wine on the plates eliminates the need for further distillations which would otherwise be necessary for a simple distillation process.

Armagnac Type Alembic includes:

Warranty of distilling system - Up to 10 years depending on usage.

In order to obtain the technical specifications and further information such as requirements, values etc. for this system, please fill in our enquiry request form with your information and enquiries.

Login